Products

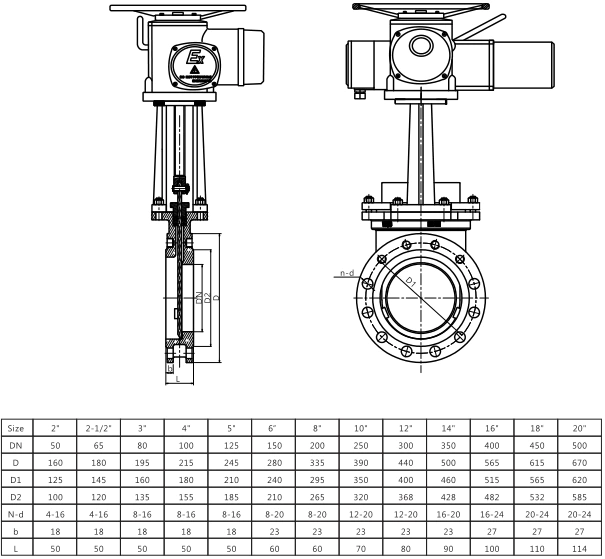

COVNA HK60-Z-S Multi Turn Electric Knife Gate Valve

Pioneers in the industry, COVNA offer electric knife gate valve, basalt line gate valve, resilient seated gate valve, resilient seated sluice valve and industrial edge gate valve. Superior grade, high efficiency, low power consumption, modular design and weather resistant best describe the quality of Motorized Knife Gate. Valves are available in wafer or lug style, as well as with cast iron bodies or stainless steel bodie.

Pioneers in the industry, COVNA offer electric knife gate valve, basalt line gate valve, resilient seated gate valve, resilient seated sluice valve and industrial edge gate valve. Superior grade, high efficiency, low power consumption, modular design and weather resistant best describe the quality of Motorized Knife Gate. Valves are available in wafer or lug style, as well as with cast iron bodies or stainless steel bodie

| Design & Manufacture | ASME B16.34, API600 |

| Face to Face | ASME B16.10 |

| Connection Dimension | ASME B16.5, ASME B16.25 |

| Inspection and Test | ISO5208, API598 |

| Size Range | 1/2in to 28in |

| Pressure | Class 150/Class 300/Class 600 |

| Medium Temperature | -30°C to 450°C |

| Material Options | Stainless steel 304/316/316L or WCB |

Stainless Steel Electric Knife Gate Valve with Multi-Turn Electric Actuator

- Application: Water treatment, paper-making, power industry, chemical industry, iron and steel industry, mining, food processing, petroleum, etc.

● There are two types of flameproof products: dⅠ and dⅡBT4

1) dⅠ is suitable for non-excavating working face of a coal mine;

2) dⅡBT4 is used for factories and suitable for the environment

● Outdoor type is used in places without flammable/explosive and non-corrosive media

● It is an explosive gas mixture of T1 ~ T4 group of Class ⅡA and ⅡB.

● Suitable Medium: Pulp, sewage, slurry coal, ash, slag-water mixture, gas.Technical Parameters of Valve Actuator

| Power supply | Conventional: single phase 220v, three-phase 380v |

| Special: three-phase 400v, 415v, 660v(50Hz, 60Hz) | |

| Working environment | Ambient temperature: -20 ~ + 60 ℃ (special temperature environment can be customized) |

| Relative humidity: 95% (at 25 ° C) | |

| Input signals | Analog quantity 4mA-20mA DC, input impedance 250Ω

On-off quantity active 24V DC The profibus-dp MODUS (optional) |

| Output signals | 4mA-20mA DC load resistance 750Ω or less

6 groups of passive contacts Profibus-DP or MODUS (optional) |

| Protection level | Outdoor type and explosion-proof type are IP55 (IP65, IP67, IP68 can be provided for special order) |

| Working system | Short time 10 minutes (15-60 minutes for special order) |

Technical Parameters of Valve Body

| Valve Body | Valve components | ||

| Nominal size | DN50-DN400 | Sealing material | PTFE,NBR,EPDM,VITON |

| Body Material | Cast Iron or Stainless Steel | Disc Material | SS304 |

| End Connection | Flange | Stem Material | Cast iron, WCB |

| Operating Pressure | 1.0 / 1.6 / 2.0 / 2.5 MPa | Applicable media | Water, Air, Gas, Oil, Liquid |

| Structure | Midline structure/A-Type | Design standard | ANSI, JIS, DIN, BS, GB |

| Valve Body | Valve components | ||

| Nominal size | DN50-DN400 | Sealing material | PTFE,NBR,EPDM,VITON |

| Body Material | Cast Iron or Stainless Steel | Disc Material | SS304 |

| End Connection | Flange | Stem Material | Cast iron, WCB |

| Operating Pressure | 1.0 / 1.6 / 2.0 / 2.5 MPa | Applicable media | Water, Air, Gas, Oil, Liquid |

| Structure | Midline structure/A-Type | Design standard | ANSI, JIS, DIN, BS, GB |